A1000

YASKAWA A1000 High Performance vector control

-The Birth of Yaskawa’s ACE Drive

- Input voltage,V

- 3PH 200V~240V

- 3PH 380V~480V

- 3PH 525V~660V

- Power range , kW

- 0.4kW~110kW

- 0.4kW~750kW

- 0.75kW~185kW

FeaturesAPPlication

Main Features:

-The Most Advanced Drive Technology

---Maximum applicable motor capacity (kW) indicates capacity under heavy-duty (HD) rating.

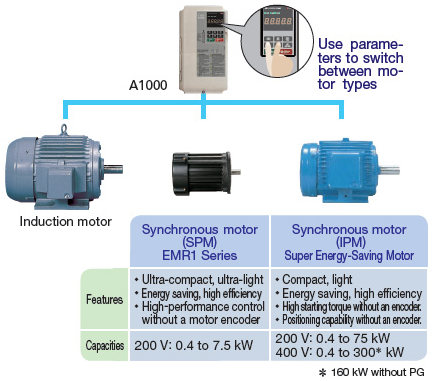

---Capable of driving any kind of motor.

A1000 runs not only induction motors, but also synchronous motors like IPM and SPM motors with high performance current vector control.--- Minimize equipment needed for your business by using the same drive to run induction and synchronous motors.

---Switch easily between motor types with a single parameter setting.

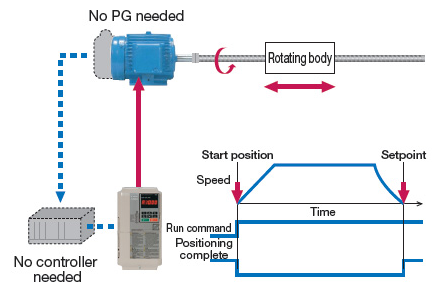

-Rotor Positioning without Motor Encoder

---Use an IPM motor to perform position control without motor feedback.

Electrical saliency in IPM motors makes it possible to detect speed, direction, and rotor position without the use of a motor encoder.---Precision positioning functionality without an up-per controller.

Visual programming in DriveWorksEZ lets the user easily create a customized position control sequence, without the use a motor encoder.

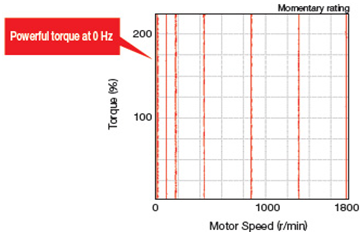

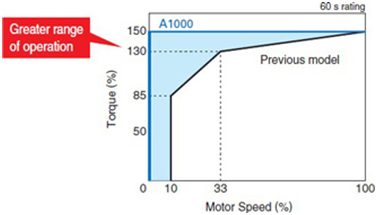

-Cutting-Edge Torque Characteristics

---Powerful torque at 0 Hz, without a motor encoder∗

Once out of reach for AC drives, Yaskawa now offers advanced control features without a motor encoder. Achieve even more powerful starting torque at zero speed with an IPM motor.·∗:No speed sensors or pole sensors required.

∗1: Achieving this torque output requires a larger capacity drive.

∗2: Contact your Yaskawa or nearest agent when using PM motors except SSR1 series or SST4 series motors manufactured by Yaskawa Motor Co., Ltd.

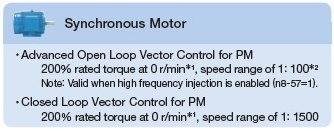

***Top Characteristics

[Advanced Open Loop Vector Control for PM with an IPM motor]

***Comparing the speed control range

[Advanced Open Loop Vector Control for PM with an IPM motor]

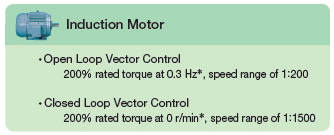

·High-performance current vector control achieves powerful starting torque with an induction motor.

Powerful starting torque with an induction motor.

*: Achieving this torque output requires a larger capacity drive.

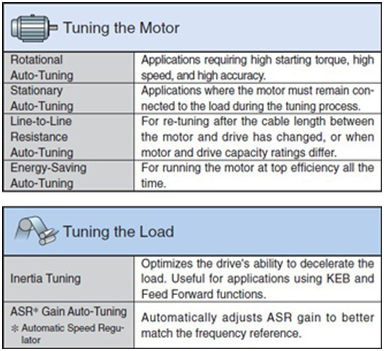

---Loaded with Auto-Tuning Features

*Auto-Tuning features optimize drive parameters for operation with induction motors as well as synchronous motors to achieve the highest performance levels possible.

*Perfects not only the drive and motor performance, but also automatically adjusts settings relative to the connected machinery.

A variety of ways to automatically optimize drive settings and performance

Note: This type of Auto-Tuning is available only for motors less than 450 kW using an encoder.

*Brand-new Auto-Tuning methods.

A1000 continuously analyzes changes in motor characteristics during run for highly precise speed control.

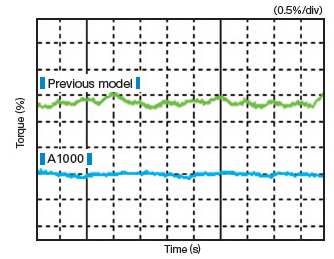

Smooth Operation

*Smooth low speed operation thanks to even better torque ripple suppression.

Comparing torque ripple at zero speed (Closed Loop Vector)

Tackling Power Loss and Recovery

*A1000 offers two ways to handle momentary power loss.

*A1000 is capable of handling momentary power loss for induction motors as well as synchronous motors without the use of a motor encoder.

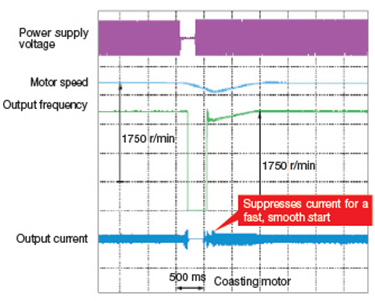

Speed search

Easily find the speed of a coasting motor for a smooth restart.

Applications: Perfect for fans, blowers, and other rotating, fluid-type applications.

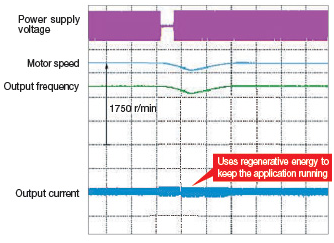

KEB

Keep the motor running without allowing it to coast.

Applications :Highly recommended for film lines and other applications requiring continuous operation.

Note: Requires a separate sensor to detect power loss.

The drive may trip depending on load conditions, and the motor coast to stop.·Ride through power loss for up to 2 seconds.∗

Crucial for semi-conductor manufacturers

No need to purchase a backup power supply

Detects, outputs an undervoltage signal during power loss

∗ :The Momentary Power Loss Recovery Unit option may be required depending on the capacity of the drive.Heavy interia loading machine, Metal machine application, Heavy loading machine application, Vertical Crane, Paper Process machine, Rolling machine etc.

Email: Bennylamap@gmail.com

Add:Unit B1-301,HuaJing Mansion,LuoJiang Economic Development Zone,362000,Quanzhou,China

Copyright © 信沃电气 Technical support Longcai Technology Group